102 Allied Parkway Sicklerville, NJ 08081

Bottle Labeling Machines

Achieve precision and efficiency with our bottle labeling solutions

Bottle labeling is about achieving a balance between aesthetics and operational efficiency. On one hand, a clean, precisely placed label reflects your brand’s professionalism and builds consumer trust at first glance. On the other, your production line needs to keep pace, especially as demand grows. That’s why choosing the right labeler isn’t just about how the final product looks; it’s also about how smoothly and reliably that label gets there.

Whether you’re applying pressure-sensitive, shrink-sleeve, or wrap-around labels, your labeling equipment must be able to handle unique bottle shapes — round, square, tapered, or custom-molded — without compromising on speed or accuracy. The right bottle labeling solution should integrate seamlessly into your existing workflow, scale with your production needs, and maintain consistent, high-quality results day after day.

Pro-Motion Industries is here to help. Our team of experts will guide you through the process to find the right bottle labeling solution for your requirements and budget. We partner with trusted manufacturers such as Auto Labe, Collamat, and CTM to provide state-of-the-art, reliable, and cost-effective machines designed to improve your labeling operations and help your brand stand out.

Explore our cutting-edge bottle labeling systems

We offer a curated range of semi-automatic and fully automatic labelers to suit any production scale.

Showing all 8 results

-

Applications

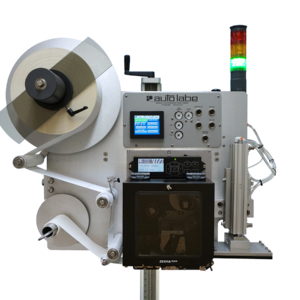

Auto Labe Model 155

Auto Labe’s new Model 155 Print & Apply system integrates a Tamp, Blow, Air-Tamp, or Smart Tamp label applicator with high performance thermal transfer and direct thermal printers. It also incorporates a color touchscreen and PLC for easy menu driven operation and control. No more relays or circuit board problems to worry about. Built to last with only the best components available for maximum versatility and performance.

-

Applications

Auto Labe Model 390s

The Model 390s uses a portable tabletop approach, uniquely designed for labeling small, round products such as test tubes, ampoules, and vials.

-

Applications

Auto Labe Model 395s

The Model 395s uses a portable tabletop approach, uniquely designed for labeling small, round products such as test tubes, ampoules, and vials.

-

Applications

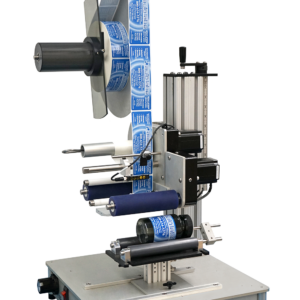

Auto Labe Model 550 Semi-Automatic

The lightweight and portable Auto Labe Model 550 offers similar functionalities as a manual dispenser. It moves individual or multiple-row labels and removes them from their lining. The difference is that instead of manually pulling on the liner, a trigger on the dispenser detects the absence of a label then advances the label.

-

Applications

Auto Labe Model 550s Semi-Automatic

The lightweight and portable Auto Labe Model 550s offers similar functionalities as a manual dispenser. It moves individual or multiple-row labels and removes them from their lining. The difference is that instead of manually pulling on the liner, a trigger on the dispenser detects the absence of a label then advances the label.

-

Applications

Auto Labe Model 560s Semi-Automatic

The lightweight and portable Auto Labe Model 560s offers similar functionalities as a manual dispenser. It moves individual or multiple-row labels and removes them from their lining. The difference is that instead of manually pulling on the liner, a trigger on the dispenser detects the absence of a label then advances the label.

-

Applications

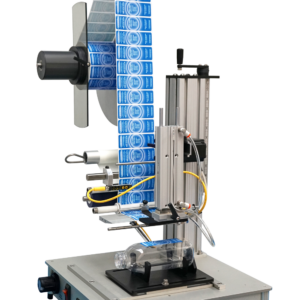

Collamat® 7300

The Collamat® 7300 is a high-performance labeler and the perfect solution for any standard application, even at high speeds or great throughput. It delivers premium, high-quality labels to products across industries, including food and beverage, pharmaceutical, storage, and logistics. With simple design and mechanical efficiency, the C7300 is easy to operate, requires minimum training and maintenance, and is an ideal investment that will yield long-term ROI.

-

Applications

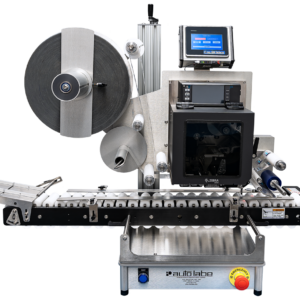

CTM Labeling Systems 360a Series Label Applicator

The 360a Series Label Applicator evolved from the industry-standard 360 Series Platform. It can be configured as a merge, blow-on, or tamp-blow applicator with 5″, 7.5″, or 10″ widths. Each module can also be easily switched to the opposite hand with few or no change parts in a minimum amount of time. All units are stepper motors, built to leverage state-of-the-art electronics and an intuitive label sensor. The 360a also comes with a smart file encryption that allows for easy on-site software revisions and upgrades.

Why should you invest in a bottle labeling machine?

A high-quality labeler can transform your operations by:

- Elevating your brand’s image with precise and consistent label placement

- Increasing production efficiency by automating repetitive labeling tasks

- Reducing labor costs by minimizing the need for manual handling

- Improving consistency and accuracy, eliminating the risk of human error

- Adapting to a variety of bottle shapes, sizes, and materials with ease

- Supporting regulatory labeling compliance for industries such as food, beverage, and pharmaceuticals

Your trusted partner in bottle labeling solutions

Since 1994, Pro-Motion Industries has been helping businesses improve their product packaging with:

Expert guidance

We match you with the right machine for your specific needs, production goals, and budget.

Top-tier labeling machines

Our relationships with leading labeling machine manufacturers such as Auto Labe, Collamat, and CTM give you access to the most reliable equipment available.

Competitive pricing

Benefit from strong manufacturer relationships without overextending your budget.

Ongoing support

From setup and training to maintenance and troubleshooting, we’re here to keep your equipment performing at its best.

Frequently asked questions about bottle labeling machines

We offer bottle labeling machines for virtually any bottle shape, including standard round (cylindrical) bottles, flat-sided or rectangular bottles, square bottles, and complex tapered or oval-shaped containers.

The key difference lies in the level of operator involvement. A semi-automatic labeler requires an operator to place each bottle into a jig or onto a roller and then activate the mechanism (often with a footswitch) to apply the label. These machines are ideal for smaller businesses, startups, or short production runs where speed is not the primary concern.

On the other hand, a fully automatic labeler is integrated into a conveyor line. It automatically separates, transports, and labels bottles without the need for operator intervention, making it perfect for large-scale production.

A print-and-apply labeler combines a label printer engine with a label applicator. This allows it to print variable, real-time information, such as manufacturing dates, expiration dates, lot codes, and/or unique barcodes, directly onto the label immediately before it is applied to the bottle.

Considering the following factors when selecting a labeling machine:

- Product and label: The size and shape of your bottle(s) and the type and size of your label

- Production speed: How many bottles you need to label per hour or day

- Application: The type of label application needed (e.g., wraparound, front/back)

- Budget: Your initial investment capacity and long-term ROI goals

Not sure which labeler fits your needs? Talk to our experts at Pro-Motion Industries. We’ll analyze your needs to recommend the perfect, most cost-effective solution.

Yes, we provide full installation support and operator training so your team can confidently run the equipment from day one.

Maintenance frequency depends on usage, but regular inspections and cleanings can extend your machine’s lifespan. We offer ongoing maintenance services to keep your system in top condition.

Your bottle labeling equipment should work as hard as you do

Let us help you find the right solution, whether you’re a small business looking for your first labeler or a large manufacturer ready to scale.